SPRAYED FIRE-RESISTANT MATERIALS

Building Code: 1704.11

All sprayed fire-resistant materials applied to floor, roof and wall assemblies and structural members as designated in the approved construction documents must be inspected. ANZ can perform visual inspection after the rough installation of all electrical, sprinkler, mechanical and plumbing systems and suspension systems for ceilings.

EXTERIOR INSULATION AND FINISH SYSTEM (EIFS)

Building Codes: 1704.13 / 2702

All Exterior Insulation and Finish Systems (EIFS) installed more than 15 feet above adjacent finished grades must be inspected. ANZ can perform visual inspection of these EIFS systems to verify compliance with the approved construction documents including proper attachment to the building’s structural, installation of waterproofing membranes, weeps, and drains. We will also check that all mold prevention features are in conformance with the manufacturer’s installation guidelines.

SMOKE CONTROL SYSTEMS

Building Code: 1704.15

All active smoke control systems including stair including smoke exhaust systems, stair pressurization systems, and elevator pressurization systems, must be inspected and tested. ANZ can perform the required visual inspection of the smoke control systems and perform the function performance testing and air balancing procedures by our of our certified air balancers.

MECHANICAL SYSTEMS

Building Code: 1704.16

All mechanical systems requiring a Certificate of Compliance by the Administrative Code Section 28-116.4.1 must be inspected for conformance with the construction documents. ANZ can perform visual inspection of all installed mechanical systems, and required testing per applicable NYC Building Codes.

FUEL-OIL STORAGE AND FUEL-OIL PIPING SYSTEMS

Building Code: 1704.17

All fuel-oil storage equipment including tanks, pumps, valves, piping, hangers and bracing, and terminals must be inspected in accordance with the contract documents. ANZ can perform visual inspection of the installed systems and verify proper testing of all fuel oil storage tanks in accordance with Section 1308 of the NYC Mechanical Code.

SOIL PERCOLATION TEST - PRIVATE ON-SITE STORM WATER DRAINAGE DISPOSAL SYSTEMS, AND DETENTION FACILITIES

Building Code: 1704.21.1.2

All soil percolation tests performed by the contractor must be performed under the supervision of a Special Inspector. ANZ can assist in overseeing the percolation tests and verify they have been performed in accordance with the provisions of Section 1114.2.2 of the NYC Plumbing Code.

PRIVATE ON-SITE STORM WATER DRAINAGE DISPOSAL SYSTEMS, AND DETENTION FACILITIES INSTALLATION

Building Code: 1704.21.2

All storm water detention and retention systems including roof detention systems must be inspected. ANZ can perform visual inspection of the installed detention facilities to ensure proper materials are used, proper placement of fill materials, adequate volume is maintained, are proper flow control devices are used. As part of the inspection we would witness a water tightness test on all detention tanks as facilitated by the Contractor.

INDIVIDUAL ON-SITE PRIVATE SEWAGE DISPOSAL SYSTEMS INSTALLATIONS

Building Code: 1704.22

All on site sewage disposal systems must be inspected. ANZ can perform visual inspection of the installed systems for conformance with the rules of the department.

SOIL PERCOLATION TEST - INDIVIDUAL ON-SITE PRIVATE SEWAGE DISPOSAL SYSTEMS

Building Code: 1704.22

All soil percolation tests performed by the contractor must be performed under the supervision of a Special Inspector. ANZ can assist in overseeing the percolation tests and verify they have been performed in accordance with the provisions of Section 1114.2.2 of the NYC Plumbing Code.

SPRINKLER SYSTEMS

Building Code: 1704.23

All new and altered sprinkler systems must be inspected. ANZ can perform visual inspection of the sprinkler systems including witness of the required hydrostatic pressure test as performed by the Licensed Fire Supression Contactor.

STANDPIPE SYSTEMS

Building Code: 1704.24

All new and altered standpipe systems must be inspected. ANZ can perform visual inspection of the standpipe systems including witness of the required hydrostatic pressure test as performed by the Licensed Fire Supression Contactor.

CHIMNEYS

Building Code: 1704.26

All new and altered boilers, chimney connectors, and heating systems must be inspected. ANZ can perform visual inspection of all required heating systems to verify compliance with the construction documents.

FIRE-RESISTANT PENETRATIONS AND JOINTS (FIRESTOP)

Building Code: 1704.27

All penetration firestop systems and fire-resistant joint systems must be inspected. ANZ can perform visual inspection of all penetrations and joints to verify compliance with standards ASTM E 2174 and ASTM E 2393.

Structural Steel - Welding

All new structural steel welds shall be inspected to confirm compliance with the construction documents. ANZ can perform visual inspection of welds in accordance with AWS D1.1.

Structural Steel - Details

The steel frame shall be inspected to verify compliance with the detail shown on the approved construction documents including bracing, stiffening, member location and proper application of joint details at each connection. ANZ can perform visual inspection of the details.

Structural Steel - High Strength Bolting

Installation of high-strength bolts are to be inspected in accordance with the construction documents. ANZ can perform visual inspection of the bolting periodically in accordance with AISC 360.

Structural Stability - Existing Buildings

Existing structures shall be inspected prior to demolition activities to verify the ability of the structural system to remain in position without incurring damage from construction activities and loading. ANZ can perform inspection of the temporary protection measures put in place in accordance with the building code and the construction documents.

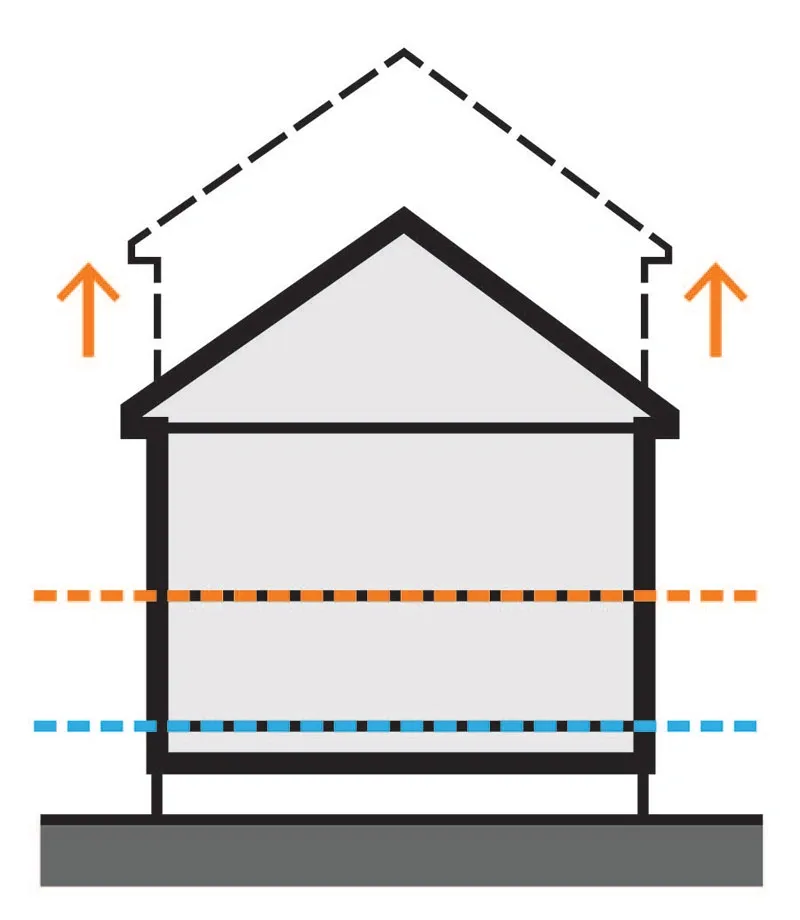

FLOOD HAZARD MITIGATION

Building Code: 1704.29, G105

All buildings located in areas of special flood hazard must be inspected. ANZ can perform inspection of buildings to verify compliance with Appendix G of the NYC Building Code. The inspection protocol will include verification of lowest floor elevation, and verification that the building has been constructed using methods and practices that minimize flood damage in accordance with the approved construction documents.

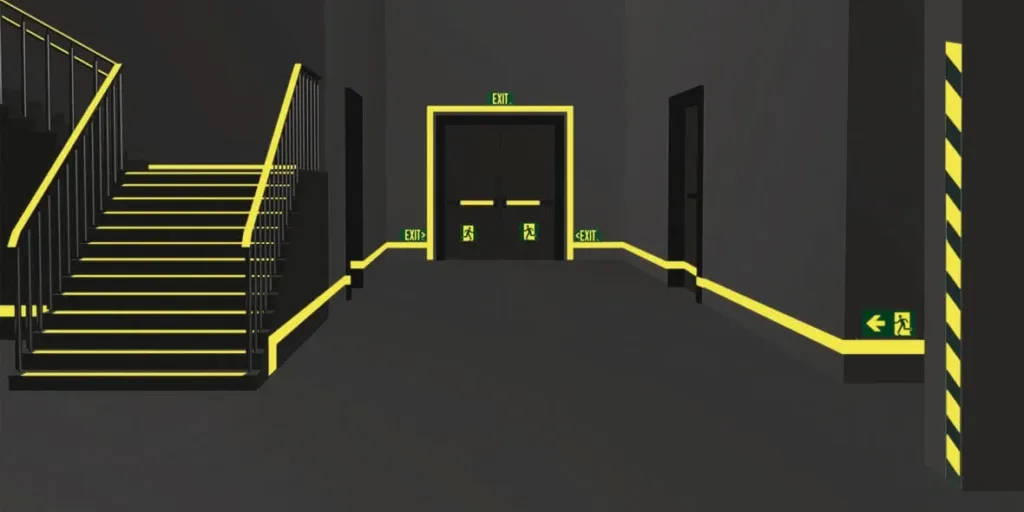

LUMINOUS EGRESS PATH MARKINGS

Building Code: 1704.30

All photoluminescent egress path markings must be inspected. ANZ can perform the visual inspection of all required markings to verify compliance with the approved construction documents, manufacturer’s installation requirements, and department rules & regulations.

EMERGENCY & STANDBY POWER SYSTEMS (GENERATORS)

Building Code: 1704.31

All photoluminescent egress path markings must be inspected. ANZ can perform the visual inspection of all required markings to verify compliance with the approved construction documents, manufacturer’s installation requirements, and department rules & regulations.

POST-INSTALLED ANCHORS

Building Code: 1704.32

All post installed anchors including mechanical anchors, adhesive anchors, and screw anchors must be inspected. ANZ can perform visual inspection of the anchor systems to ensure the installation is being performed in accordance with the Manufacturer’s Printed Installation Instructions (MPII). We can also perform proof-load testing using one of our hydraulicaly actuated pull-testing devices.

SEISMIC ISOLATION SYSTEMS

Building Code: 1707.8

Building Structures designated in Seismic Design Category C or D must be inspected for proper seismic isolation system installation. ANZ can perform visual inspection of all required mechanical, plumbing, fuel gas, and electrical components to confirm compliance with the approved construction documents.

PROTECTION OF EXPOSED FOUNDATION INSULATION

Insulation will be visually inspected to verify proper protection where appied to the exteior of cellar walls, crawl space walls and at the perimeter of slab on grade floors.

INSULATION PLACEMENT & R-VALUES

Insulation will be visually inspected to verify proper protection where appied to the exteior of cellar walls, crawl space walls and at the perimeter of slab on grade floors.

FENESTRATION AND DOOR U FACTOR AND PRODUCT RATINGS

FENESTRATION AIR LEAKAGE

FENESTRATION AREAS

AIR BARRIER TESTING

AIR BARRIER CONTINUITY PLAN TESTING

Insulation will be visually inspected to verify proper protection where appied to the exteior of cellar walls, crawl space walls and at the perimeter of slab on grade floors.

VESTIBULES

MECHANICAL AND SERVICE WATER HEATING INSPECTIONS

FIREPLACES

SHUTOFF DAMPERS

HVAC-R, COMMERCIAL KITCHEN EQUIPMENT, AND SERVICE WATER HEATING EQUIPMENT

HVAC-R AND SERVICE WATER HEATING SYSTEM CONTROLS

IB4

HVAC-R AND SERVICE WATER PIPING DESIGN & INSULATION

IB5

DUCT LEAKAGE TESTING, INSULATION AND DESIGN - IB6

IB6

ELECTRICAL POWER AND LIGHTING SYSTEMS

METERING – IIC1

Visual inspection will be performed to confirm the presence of all required meters for monitoring total electrical energy usage and/or total fuel use.

LIGHTING IN DWELLING UNITS – IIC2

All lamps will be visually inspected to verify compliance with the code’s high efficacy requirements.

INTERIOR LIGHTING POWER – IIC3

All installed interior lighting shall be visually inspected to verify compliance with the lighting power allowances as indicated on the contract documents.

EXTERIOR LIGHTING POWER – IIC4

All installed exterior lighting shall be visually inspected to verify compliance with the lighting power allowances as indicated on the contract documents.

LIGHTING CONTROLS – IIC5

Installed lighting controls systems will be both visually inspected and tested for proper functionality in accordance with the contract documents. This will include:

▪ occupant sensors

▪ manual interior lighting controls

▪ light-reduction controls

▪ automatic lighting shutoff

▪ daylight zone controls

▪ sleeping unit controls

▪ exterior lighting controls

▪ egress illumination controls

PROOF-LOADING

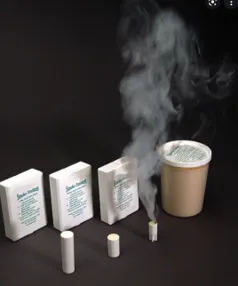

SPRINKLER HYDROSTATIC PRESSURE TESTING

SMOKE TESTING

BLOWER DOOR TESTING

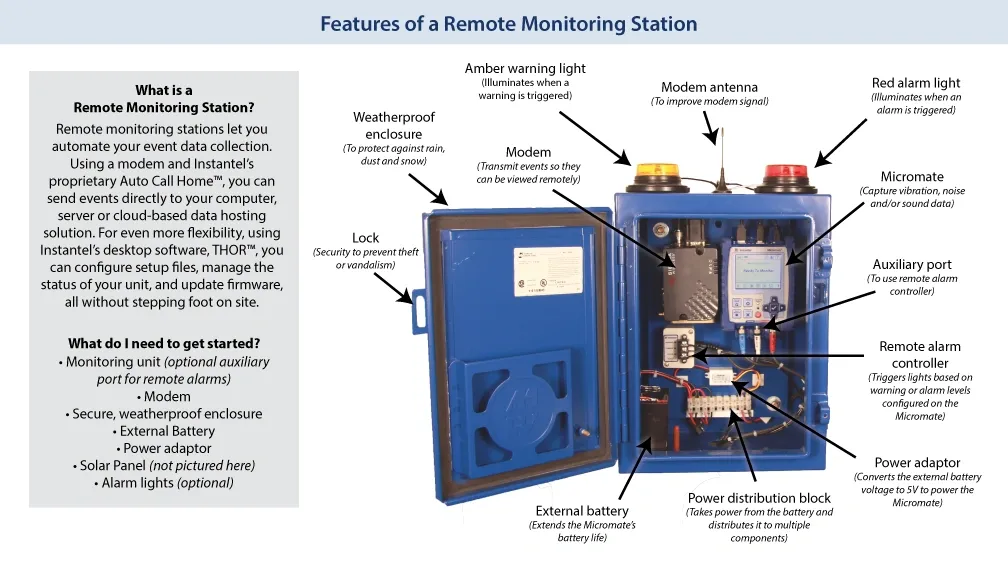

VIBRATION MONITORING

The New York City Building Code requires monitoring of adjacent building structures within certain distances when excavation work is performed per section 330.9.4.4., and during underpinning procedures in accordance with Section 1814.

Monitoring services are performed in accordance with a monitoring plan developed by the project’s registered design professional indicating the scope, frequency of monitoring, acceptable tolerances, and reporting criteria for when tolerances are exceeded.

ANZ Inspections and Testing Laboratory performs all monitoring services using reliable vibration monitor assemblies complete with multiple types of triaxial geophones. Each assembly is deployed to the job site in a weather-protected case with an internal wireless router for transmission of all data to a remote central station. When permanent power is not available on site, we can provide battery stations or solar panels for on-site power generation.

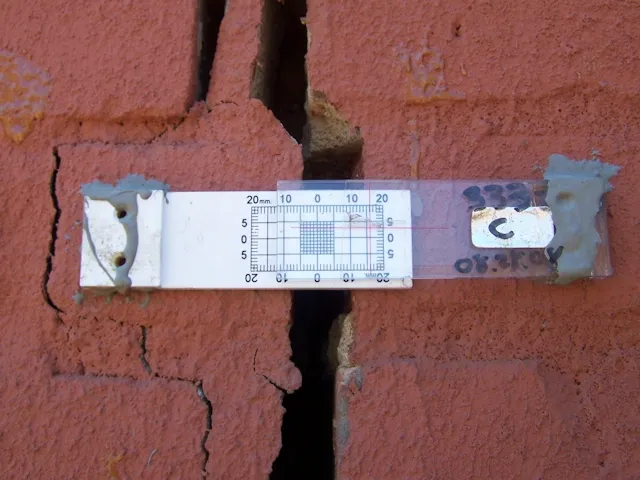

CRACK MONITORING

OPTICAL MONITORING